Page 116 - Plastic Process Equipment, Inc

P. 116

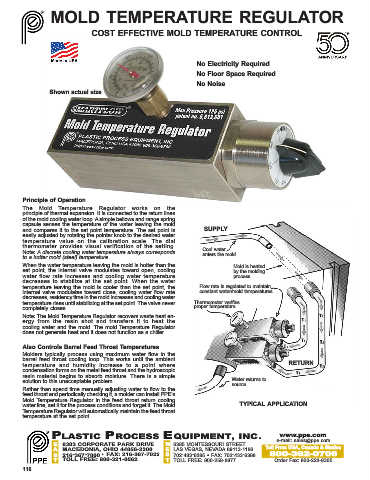

MOLD TEMPERATURE REGULATOR

COST EFFECTIVE MOLD TEMPERATURE CONTROL

No Electricity Required

No Floor Space Required

No Noise

Shown actual size

Principle of Operation

The Mold Temperature Regulator works on the

principle of thermal expansion. It is connected to the return lines

of the mold cooling water loop. A simple bellows and range spring

capsule senses the temperature of the water leaving the mold

and compares it to the set point temperature. The set point is SUPPLY

easily adjusted by rotating the pointer knob to the desired water

temperature value on the calibration scale. The dial

thermometer provides visual verification of the setting. Cool water

Note: A discrete cooling water temperature always corresponds enters the mold.

to a hotter mold (steel) temperature.

When the water temperature leaving the mold is hotter than the Mold is heated

set point, the internal valve modulates toward open, cooling by the molding

water flow rate increases and cooling water temperature process.

decreases to stabilize at the set point. When the water

temperature leaving the mold is cooler than the set point, the Flow rate is regulated to maintain

internal valve modulates toward close, cooling water flow rate constant water/mold temperatures.

decreases, residency time in the mold increases and cooling water

temperature rises until stabilizing at the set point. The valve never Thermometer verifies

completely closes. proper temperature.

Note: The Mold Temperature Regulator recovers waste heat en-

ergy from the resin shot and transfers it to heat the

cooling water and the mold. The mold Temperature Regulator

does not generate heat and it does not function as a chiller.

Also Controls Barrel Feed Throat Temperatures

Molders typically process using maximum water flow in the

barrel feed throat cooling loop. This works until the ambient

temperature and humidity increase to a point where RETURN

condensation forms on the metal feed throat and the hydroscopic

resin material begins to absorb moisture. There is a simple Water returns to

solution to this unacceptable problem.

source.

Rather than spend time manually adjusting water to flow to the

feed throat and periodically checking it, a molder can install PPE’s

Mold Temperature Regulator in the feed throat return cooling

water line, set it for the process conditions and forget it. The Mold TYPICAL APPLICATION

Temperature Regulator will automatically maintain the feed throat

temperature at the set point.

PLASTIC PROCESS EQUIPMENT, INC. www.ppe.com

e-mail: sales@ppe.com

E 8303 CORPORATE PARK DRIVE W 6385 MONTESSOURI STREET

A MACEDONIA, OHIO 44056-2300 E LAS VEGAS, NEVADA 89113-1186 Toll Free: USA, Canada & Mexico

S 216-367-7000 • FAX: 216-367-7022 S 702-433-6385 • FAX: 702-433-6388 800-362-0706

T TOLL FREE: 800-321-0562 T TOLL FREE: 800-258-8877 Order Fax: 800-223-8305

116