Page 121 - Plastic Process Equipment, Inc

P. 121

®

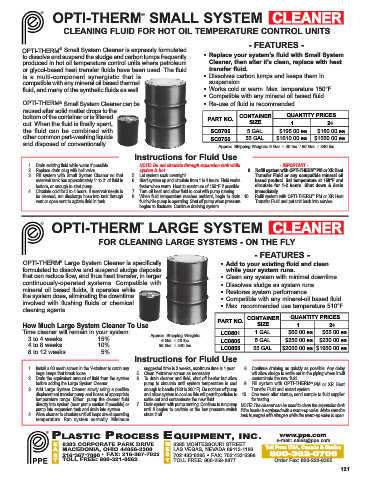

OPTI-THERM SMALL SYSTEM CLEANER

CLEANING FLUID FOR HOT OIL TEMPERATURE CONTROL UNITS

- FEATURES -

OPTI-THERM Small System Cleaner is expressly formulated

®

to dissolve and suspend the sludge and carbon lumps frequently • Replace your system's fluid with Small System

produced in hot oil temperature control units where petroleum Cleaner, then after it's clean, replace with heat

or glycol-based heat transfer fluids have been used. The fluid transfer fluid.

is a multi-component synergistic that is • Dissolves carbon lumps and keeps them in

compatible with any mineral oil based thermal suspension.

fluid, and many of the synthetic fluids as well. • Works cold or warm. Max. temperature 150°F.

• Compatible with any mineral oil based fluid.

®

OPTI-THERM Small System Cleaner can be • Re-use of fluid is recommended.

reused after solid matter drops to the

bottom of the container or is filtered PART NO. CONTAINER QUANTITY PRICES

out. When the fluid is finally spent, SIZE 1 2+

the fluid can be combined with SC0705 5 GAL. $195.00 ea. $180.00 ea.

other common part-washing liquids SC0755 55 GAL. $1610.00 ea. $1550.00 ea.

and disposed of conventionally.

Approx. Shipping Weights: 5 Gal. = 40 lbs. / 55 Gal. = 440 lbs.

Instructions for Fluid Use

1. Drain existing fluid while warm if possible. NOTE: Do not circulate through expansion tank while - IMPORTANT -

2. Replace drain plug with ball valve. system is hot. 9. Refill system with OPTI-THERM PM or XR Heat

®

3. Fill system with Small System Cleaner so that 5. Let system soak overnight. Transfer Fluid or any compatible mineral oil

reservoir tank has approximately 1" to 2" of fluid in 6. Start system up and circulate from 1 to 4 hours. Fluid works based product. Set temperature at 150°F and

bottom, or enough to start pump. faster when warm. Heat to maximum of 150°F if possible. circulate for 1-2 hours. Shut down & drain

4. Circulate cold for 3 to 4 hours. If reservoir needs to 7. Turn off heat and allow fluid to cool with pump running. immediately.

®

be cleaned, run discharge hose into tank through 8. When fluid temperature reaches ambient, begin to drain 10. Refill system with OPTI-THERM PM or XR Heat

vent or open vent to agitate fluid in tank. fluid while pump is operating. Shut off pump when pressure Transfer Fluid and put unit back into service.

begins to fluctuate. Continue draining system.

OPTI-THERM LARGE SYSTEM CLEANER

®

FOR CLEANING LARGE SYSTEMS - ON THE FLY

- FEATURES -

OPTI-THERM Large System Cleaner is specifically • Add to your existing fluid and clean

®

formulated to dissolve and suspend sludge deposits while your system runs.

that can reduce flow, and thus heat transfer, in larger • Clean any system with minimal downtime

continuously-operated systems. Compatible with • Dissolves sludge as system runs

mineral oil based fluids, it operates while • Restores system performance

the system does, eliminating the downtime • Compatible with any mineral-oil based fluid

involved with flushing fluids or chemical

cleaning agents. • Max. recommended use temperature 510°F

CONTAINER QUANTITY PRICES

PART NO.

How Much Large System Cleaner To Use SIZE 1 2+

Time cleaner will remain in your system: LC0801 1 GAL. $60.00 ea. $55.00 ea.

3 to 4 weeks ................... 15% Approx. Shipping Weights: LC0805 5 GAL. $250.00 ea. $230.00 ea.

5 Gal. = 40 lbs.

4 to 8 weeks ................... 10% 55 Gal. = 440 lbs. LC0855 55 GAL. $2050.00 ea. $1950.00 ea.

8 to 12 weeks ................... 5%

Instructions for Fluid Use

1. Install a 60 mesh screen in the Y-strainer to catch any suggested time is 3 weeks, maximum time is 1 year. 8. Continue draining as quickly as possible. Any delay

large lumps that break loose. 5. Clean Y-strainer screen as necessary. will allow sludge to settle out in the piping where it will

2. Drain the equivalent amount of fluid from the system 6. To drain cleaner and fluid, shut off heater but allow contaminate the new fluid.

before adding the Large System Cleaner. pump to circulate until system temperature is cool 9. Fill system with OPTI-THERM PM or XR Heat

®

3. Add Large System Cleaner slowly using a positive enough to handle (180 to 200°F). Do not turn off pump Transfer Fluid and restart system.

displacement transfer pump and hoses of appropriate and allow system to cool as this will permit particles to 10. One week after startup, send sample to fluid supplier

temperature range. Either pump the cleaner fluid settle out and contaminate the new fluid. for testing.

directly into system (near pump suction if possible) or 7. Drain system with pump running. Continue to run pump NOTE: The cleaner can be used to clean the expansion tank

pump into expansion tank and drain into system. until it begins to cavitate or the low pressure switch if the heater is equipped with a warm-up valve. Make sure the

4. Allow cleaner to circulate until all loops are at operating shuts it off. tank is purged with nitrogen while the warm-up valve is open.

temperature. Run system normally. Minimum

PLASTIC PROCESS EQUIPMENT, INC. www.ppe.com

e-mail: sales@ppe.com

E 8303 CORPORATE PARK DRIVE W 6385 MONTESSOURI STREET

A MACEDONIA, OHIO 44056-2300 E LAS VEGAS, NEVADA 89113-1186 Toll Free: USA, Canada & Mexico

S 216-367-7000 • FAX: 216-367-7022 S 702-433-6385 • FAX: 702-433-6388 800-362-0706

T TOLL FREE: 800-321-0562 T TOLL FREE: 800-258-8877 Order Fax: 800-223-8305

121