Page 111 - Plastic Process Equipment, Inc

P. 111

HONEYCOMB DESICCANT ROTOR DRYERS

THE LATEST HONEYCOMB MATRIX DESICCANT ROTOR WHEEL TECHNOLOGY

Closed Loop Operating Air Flow + Continuous Rotor Rotation = Continuous Dry Air!

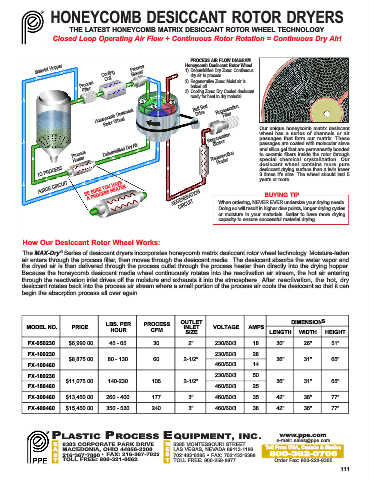

PROCESS AIR FLOW DIAGRAM

Material Hopper Cooling Process Honeycomb Desiccant Rotor Wheel

1) Dehumidified Dry Zone: Continuous

Blower

dry air to process.

Process Coil 2) Regenerative Zone: Moist air is

baked off.

Filter 3) Cooling Zone: Dry Cooled desiccant

ready for heat to dry material.

1 2

3 Belt Bed Regeneration

Honeycomb Desiccant Drive Filter

Rotor Wheel

Our unique honeycomb matrix desiccant

Regeneration wheel has a series of channels or air

passages that form our matrix. These

Blower

Dehumidified Dry Air passages are coated with molecular sieve

and silica gel that are permanently bonded

Process Regeneration to ceramic fibers inside the rotor through

Heater Heater special chemical crystalization. Our

desiccant wheel contains more pure

TO PROCESS desiccant drying surface than a twin tower

3 times it’s size. The wheel should last 5

years or more.

PURGE CIRCUIT BE SURE YOU HAVE REGENERATION BUYING TIP

A PROCESS HEATER

CIRCUIT

When ordering, NEVER EVER undersize your drying needs.

Doing so will result in higher dew points, longer drying cycles

or moisture in your materials. Better to have more drying

capacity to ensure successful material drying.

How Our Desiccant Rotor Wheel Works:

®

The MAX-Dry Series of desiccant dryers incorporates honeycomb matrix desiccant rotor wheel technology. Moisture-laden

air enters through the process filter, then moves through the desiccant media. The desiccant absorbs the water vapor and

the dryed air is then delivered through the process outlet through the process heater then directly into the drying hopper.

Because the honeycomb desiccant media wheel continuously rotates into the reactivation air stream, the hot air entering

through the reactivation inlet drives off the moisture and exhausts it into the atmosphere. After reactivation, the hot, dry

desiccant rotates back into the process air stream where a small portion of the process air cools the desiccant so that it can

begin the absorption process all over again.

OUTLET DIMENSIONS

LBS. PER PROCESS

MODEL NO. PRICE INLET VOLTAGE AMPS

HOUR CFM

SIZE LENGTH WIDTH HEIGHT

FX-050230 $6,990.00 45 - 65 30 2" 230/60/3 18 30" 26" 51"

FX-100230 230/60/3 28

$8,875.00 80 - 130 60 2-1/2" 36" 31" 65"

FX-100460 460/60/3 14

FX-180230 230/60/3 50

$11,075.00 140-230 106 2-1/2" 36" 31" 65"

FX-180460 460/60/3 25

FX-300460 $13,450.00 260 - 400 177 3" 460/60/3 35 42" 36" 77"

FX-400460 $15,450.00 350 - 530 240 3" 460/60/3 38 42" 36" 77"

PLASTIC PROCESS EQUIPMENT, INC. www.ppe.com

e-mail: sales@ppe.com

E 8303 CORPORATE PARK DRIVE W 6385 MONTESSOURI STREET

A MACEDONIA, OHIO 44056-2300 E LAS VEGAS, NEVADA 89113-1186 Toll Free: USA, Canada & Mexico

S 216-367-7000 • FAX: 216-367-7022 S 702-433-6385 • FAX: 702-433-6388 800-362-0706

T TOLL FREE: 800-321-0562 T TOLL FREE: 800-258-8877 Order Fax: 800-223-8305

111