Page 733 - Plastic Process Equipment, Inc

P. 733

EDGE PLUS TOUCHSCREEN

HOT RUNNER TEMPERATURE CONTROL SYSTEM

CONTROL ALGORITHM

The EDGE Plus Pinpoint Control Technology uses an advanced form of

adaptive fuzzy logic with PID algorithm, allowing the EDGE Plus to control

virtually any type and size of heater within +/- 0.1°F (0.05°C).

ENHANCED DATA MONITORING

The EDGE Plus monitors various aspects of the heater as it is running. Max

resistance and max wattage of the individual heaters are also recorded with

the max current. Along with recorded max values, users can monitor running

wattage, resistance and current of the heaters in real time in the Zone Details

screen. Current is constantly monitored in real time to track errors including

over-current conditions, shorted Triac and open Triac/Heater/Fuse.

PLASTIC LEAKAGE DETECTION

The EDGE Plus early leak detection will alert the user to variances in the

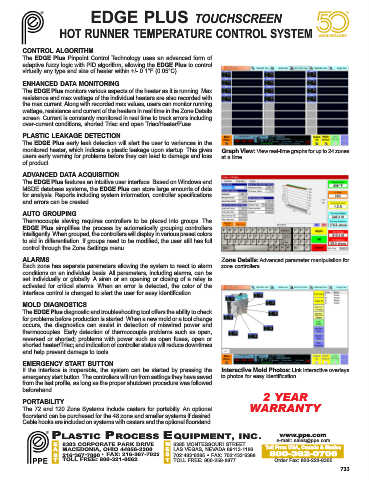

monitored heater, which indicate a plastic leakage upon startup. This gives Graph View: View real-time graphs for up to 24 zones

users early warning for problems before they can lead to damage and loss at a time.

of product.

ADVANCED DATA ACQUISITION

The EDGE Plus features an intuitive user interface. Based on Windows and

MSDE database systems, the EDGE Plus can store large amounts of data

for analysis. Reports including system information, controller specifications

and errors can be created.

AUTO GROUPING

Thermocouple slaving requires controllers to be placed into groups. The

EDGE Plus simplifies the process by automatically grouping controllers

intelligently. When grouped, the controllers will display in various preset colors

to aid in differentiation. If groups need to be modified, the user still has full

control through the Zone Settings menu.

ALARMS Zone Details: Advanced parameter manipulation for

Each zone has separate parameters allowing the system to react to alarm zone controllers.

conditions on an individual basis. All parameters, including alarms, can be

set individually or globally. A siren or an opening or closing of a relay is

activated for critical alarms. When an error is detected, the color of the

interface control is changed to alert the user for easy identification.

MOLD DIAGNOSTICS

The EDGE Plus diagnostic and troubleshooting tool offers the ability to check

for problems before production is started. When a new mold or a tool change

occurs, the diagnostics can assist in detection of miswired power and

thermocouples. Early detection of thermocouple problems such as open,

reversed or shorted; problems with power such as open fuses, open or

shorted heater/Triac; and indication of controller status will reduce downtimes

and help prevent damage to tools.

EMERGENCY START BUTTON

If the interface is inoperable, the system can be started by pressing the Interactive Mold Photos: Link interactive overlays

emergency start button. The controllers will run from settings they have saved to photos for easy identification.

from the last profile, as long as the proper shutdown procedure was followed

beforehand.

2 YEAR

PORTABILITY

The 72 and 120 Zone Systems include casters for portabilty. An optional WARRANTY

floorstand can be purchased for the 48 zone and smaller systems if desired.

Cable hooks are included on systems with casters and the optional floorstand.

PLASTIC PROCESS EQUIPMENT, INC. www.ppe.com

e-mail: sales@ppe.com

E 8303 CORPORATE PARK DRIVE W 6385 MONTESSOURI STREET

A MACEDONIA, OHIO 44056-2300 E LAS VEGAS, NEVADA 89113-1186 Toll Free: USA, Canada & Mexico

S 216-367-7000 • FAX: 216-367-7022 S 702-433-6385 • FAX: 702-433-6388 800-362-0706

T TOLL FREE: 800-321-0562 T TOLL FREE: 800-258-8877 Order Fax: 800-223-8305

733