Page 1105 - Plastic Process Equipment, Inc

P. 1105

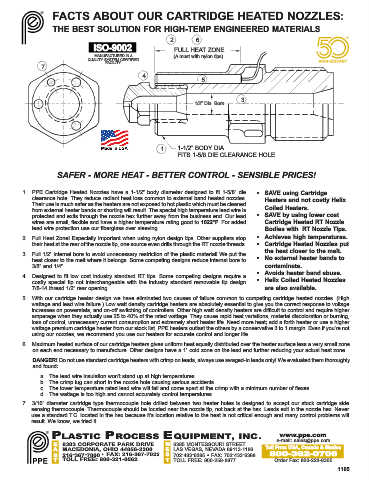

FACTS ABOUT OUR CARTRIDGE HEATED NOZZLES:

THE BEST SOLUTION FOR HIGH-TEMP ENGINEERED MATERIALS

2 6

ISO-9002 FULL HEAT ZONE

MANUFACTURED IN A (A must with nylon tips)

QUALITY SYSTEM CERTIFIED

FACILITY.

7

4

5

3

1/2” Dia. Bore

1 1-1/2” BODY DIA.

FITS 1-5/8 DIE CLEARANCE HOLE

SAFER - MORE HEAT - BETTER CONTROL - SENSIBLE PRICES!

1. PPE Cartridge Heated Nozzles have a 1-1/2” body diameter designed to fit 1-5/8” die • SAVE using Cartridge

clearance hole. They reduce radiant heat loss common to external band heated nozzles. Heaters and not costly Helix

Their use is much safer as the heaters are not exposed to hot plastic which must be cleaned Coiled Heaters.

from external heater bands or shorting will result. The special high temperature lead wire is

protected and exits through the nozzle hex further away from the business end. Our lead • SAVE by using lower cost

wires are small, flexible and have a higher temperature rating good to 1022°F. For added Cartridge Heated RT Nozzle

lead wire protection use our fiberglass over sleeving. Bodies with RT Nozzle Tips.

• Achieves high temperatures.

2. Full Heat Zone! Especially important when using nylon design tips. Other suppliers stop

their heat at the rear of the nozzle tip, one source even drills through the RT nozzle threads. • Cartridge Heated Nozzles put

the heat closer to the melt.

3. Full 1/2” internal bore to avoid unnecessary restriction of the plastic material! We put the

heat closer to the melt where it belongs. Some competing designs reduce internal bore to • No external heater bands to

3/8” and 1/4”. contaminate.

• Avoids heater band abuse.

4. Designed to fit low cost industry standard RT tips. Some competing designs require a

costly special tip not interchangeable with the industry standard removable tip design • Helix Coiled Heated Nozzles

7/8-14 thread 1/2” rear opening. are also available.

5. With our cartridge heater design we have eliminated two causes of failure common to competing cartridge heated nozzles. (High

wattage and lead wire failure.) Low watt density cartridge heaters are absolutely essential to give you the correct response to voltage

increases on powerstats, and on-off switching of controllers. Other high watt density heaters are difficult to control and require higher

amperage when they actually use 25 to 40% of the rated wattage. They cause rapid heat variations, material discoloration or burning,

loss of control, unnecessary current consumption and extremely short heater life. Need more heat; add a forth heater or use a higher

wattage premium cartridge heater from our stock list. PPE heaters outlast the others by a conservative 3 to 1 margin. Even if you’re not

using our nozzles, we recommend you use our heaters for accurate control and longer life.

6. Maximum heated surface of our cartridge heaters gives uniform heat equally distributed over the heater surface less a very small zone

on each end necessary to manufacture. Other designs have a 1” cold zone on the lead end further reducing your actual heat zone.

DANGER! Do not use standard cartridge heaters with crimp on leads, always use swaged-in leads only! We evaluated them thoroughly

and found:

a. The lead wire insulation won’t stand up at high temperatures.

b. The crimp lug can short in the nozzle hole causing serious accidents.

c. The lower temperature rated lead wire will fail and come apart at the crimp with a minimum number of flexes.

d. The wattage is too high and cannot accurately control temperatures.

7. 3/16” diameter cartridge type thermocouple hole drilled between two heater holes is designed to accept our stock cartridge side

sensing thermocouple. Thermocouple should be located near the nozzle tip, not back at the hex. Leads exit in the nozzle hex. Never

use a standard T.C. located in the hex because it’s location relative to the heat is not critical enough and many control problems will

result. We know, we tried it.

PLASTIC PROCESS EQUIPMENT, INC. www.ppe.com

e-mail: sales@ppe.com

E 8303 CORPORATE PARK DRIVE W 6385 MONTESSOURI STREET

A MACEDONIA, OHIO 44056-2300 E LAS VEGAS, NEVADA 89113-1186 Toll Free: USA, Canada & Mexico

S 216-367-7000 • FAX: 216-367-7022 S 702-433-6385 • FAX: 702-433-6388 800-362-0706

T TOLL FREE: 800-321-0562 T TOLL FREE: 800-258-8877 Order Fax: 800-223-8305

1105