Page 697 - Plastic Process Equipment, Inc

P. 697

PRINCIPLES OF THERMOCOUPLES & RTD'S

— THERMOCOUPLES —

GENERAL INFORMATION

Thermocouples are the most widely used devices to measure temperature. In their simplest form they consist of a welded

junction, called the hot junction, between two dissimilar metals (e.g. - iron & constantan, Type J) and a reference junction at

the other end of the lead wires. The hot junction will create an EMF, which can be measured at the reference junction, that

corresponds to a specific temperature. Advantages of using a thermocouple include a wide temperature range, ruggedness,

fast response time, and low cost. PPE Thermocouples are ROHS Compliant.

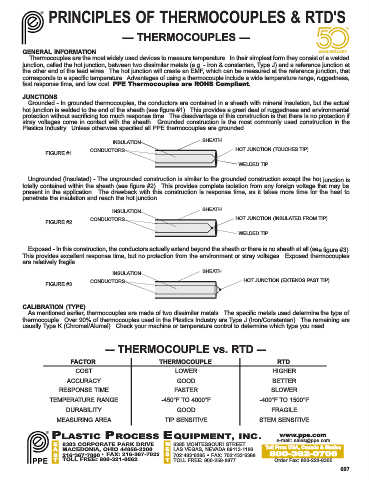

JUNCTIONS

Grounded - In grounded thermocouples, the conductors are contained in a sheath with mineral insulation, but the actual

hot junction is welded to the end of the sheath (see figure #1). This provides a great deal of ruggedness and environmental

protection without sacrificing too much response time. The disadvantage of this construction is that there is no protection if

stray voltages come in contact with the sheath. Grounded construction is the most commonly used construction in the

Plastics Industry. Unless otherwise specified all PPE thermocouples are grounded.

INSULATION SHEATH

CONDUCTORS HOT JUNCTION (TOUCHES TIP)

FIGURE #1

WELDED TIP

Ungrounded (Insulated) - The ungrounded construction is similar to the grounded construction except the hot junction is

totally contained within the sheath (see figure #2). This provides complete isolation from any foreign voltage that may be

present in the application. The drawback with this construction is response time, as it takes more time for the heat to

penetrate the insulation and reach the hot junction.

INSULATION SHEATH

CONDUCTORS HOT JUNCTION (INSULATED FROM TIP)

FIGURE #2

WELDED TIP

Exposed - In this construction, the conductors actually extend beyond the sheath or there is no sheath at all (see figure #3).

This provides excellent response time, but no protection from the environment or stray voltages. Exposed thermocouples

are relatively fragile.

INSULATION SHEATH

CONDUCTORS HOT JUNCTION (EXTENDS PAST TIP)

FIGURE #3

CALIBRATION (TYPE)

As mentioned earlier, thermocouples are made of two dissimilar metals. The specific metals used determine the type of

thermocouple. Over 90% of thermocouples used in the Plastics Industry are Type J (Iron/Constantan). The remaining are

usually Type K (Chromel/Alumel). Check your machine or temperature control to determine which type you need.

— THERMOCOUPLE vs. RTD —

FACTOR THERMOCOUPLE RTD

COST LOWER HIGHER

ACCURACY GOOD BETTER

RESPONSE TIME FASTER SLOWER

TEMPERATURE RANGE -450°F TO 4000°F -400°F TO 1500°F

DURABILITY GOOD FRAGILE

MEASURING AREA TIP SENSITIVE STEM SENSITIVE

PLASTIC PROCESS EQUIPMENT, INC. www.ppe.com

e-mail: sales@ppe.com

E 8303 CORPORATE PARK DRIVE W 6385 MONTESSOURI STREET

A MACEDONIA, OHIO 44056-2300 E LAS VEGAS, NEVADA 89113-1186 Toll Free: USA, Canada & Mexico

S 216-367-7000 • FAX: 216-367-7022 S 702-433-6385 • FAX: 702-433-6388 800-362-0706

T TOLL FREE: 800-321-0562 T TOLL FREE: 800-258-8877 Order Fax: 800-223-8305

697