Page 136 - Plastic Process Equipment, Inc

P. 136

OIL ANALYSIS SERVICE

REDUCE DOWNTIME - INCREASE PRODUCTIVITY

LET US ANALYZE YOUR OIL!

PROTECT YOUR EQUIPMENT What Do I Get For My Investment

In Oil Analysis?

• Reduction in unexpected failures

• Increased availability of equipment and

less down time.

• Reduce oil disposal costs by only changing

worn out oil.

• Longer equipment life.

• Reduced reject rates.

• Reduced spare parts inventory.

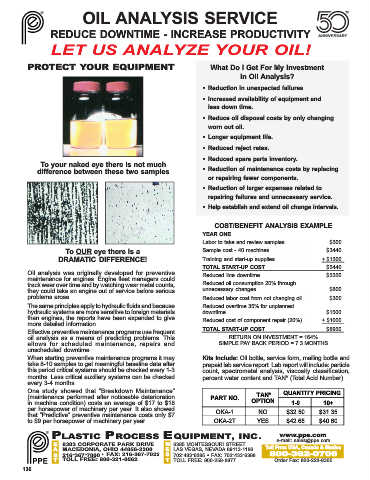

To your naked eye there is not much

difference between these two samples • Reduction of maintenance costs by replacing

or repairing fewer components.

• Reduction of larger expenses related to

repairing failures and unnecessary service.

• Help establish and extend oil change intervals.

COST/BENEFIT ANALYSIS EXAMPLE

YEAR ONE

Labor to take and review samples................... $500

To OUR eye there is a Sample cost - 40 machines............................. $3440

DRAMATIC DIFFERENCE! Training and start-up supplies......................... + $1500

TOTAL START-UP COST $5440

Oil analysis was originally developed for preventive Reduced line downtime................................... $5350

maintenance for engines. Engine fleet managers could

track wear over time and by watching wear metal counts, Reduced oil consumption 20% through

they could take an engine out of service before serious unnecessary changes..................................... $800

problems arose. Reduced labor cost from not changing oil....... $300

The same principles apply to hydraulic fluids and because Reduced overtime 35% for unplanned

hydraulic systems are more sensitive to foreign materials downtime......................................................... $1500

than engines, the reports have been expanded to give Reduced cost of component repair (20%)....... + $1000

more detailed information.

TOTAL START-UP COST $8950

Effective preventive maintenance programs use frequent

oil analysis as a means of predicting problems. This RETURN ON INVESTMENT = 164%

allows for scheduled maintenance, repairs and SIMPLE PAY BACK PERIOD = 7.3 MONTHS

unscheduled downtime.

When starting preventive maintenance programs it may Kits Include: Oil bottle, service form, mailing bottle and

take 8-10 samples to get meaningful baseline data after prepaid lab service report. Lab report will include: particle

this period critical systems should be checked every 1-3 count, spectrometal analysis, viscosity classification,

months. Less critical auxiliary systems can be checked percent water content and TAN* (Total Acid Number).

every 3-4 months.

One study showed that “Breakdown Maintenance” QUANTITY PRICING

(maintenance performed after noticeable deterioration PART NO. TAN*

in machine condition) costs an average of $17 to $18 OPTION 1-9 10+

per horsepower of machinery per year. It also showed OKA-1 NO $32.50 $31.35

that “Predictive” preventive maintenance costs only $7

to $9 per horsepower of machinery per year. OKA-2T YES $42.65 $40.60

PLASTIC PROCESS EQUIPMENT, INC. www.ppe.com

e-mail: sales@ppe.com

E 8303 CORPORATE PARK DRIVE W 6385 MONTESSOURI STREET

A MACEDONIA, OHIO 44056-2300 E LAS VEGAS, NEVADA 89113-1186 Toll Free: USA, Canada & Mexico

S 216-367-7000 • FAX: 216-367-7022 S 702-433-6385 • FAX: 702-433-6388 800-362-0706

T TOLL FREE: 800-321-0562 T TOLL FREE: 800-258-8877 Order Fax: 800-223-8305

136