Page 530 - Plastic Process Equipment, Inc

P. 530

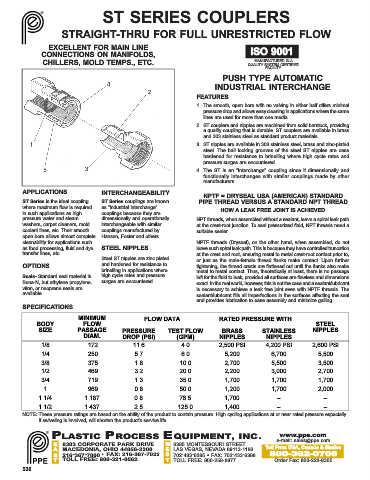

ST SERIES COUPLERS

STRAIGHT-THRU FOR FULL UNRESTRICTED FLOW

EXCELLENT FOR MAIN LINE

CONNECTIONS ON MANIFOLDS, ISO 9001

CHILLERS, MOLD TEMPS., ETC. MANUFACTURED IN A

QUALITY SYSTEM CERTIFIED

FACILITY.

PUSH TYPE AUTOMATIC

INDUSTRIAL INTERCHANGE

FEATURES

1. The smooth, open bore with no valving in either half offers minimal

pressure drop and allows easy cleaning in applications where the same

lines are used for more than one media.

2. ST couplers and nipples are machined from solid barstock, providing

a quality coupling that is durable. ST couplers are available in brass

and 303 stainless steel as standard product materials.

3. ST nipples are available in 303 stainless steel, brass and zinc-plated

steel. The ball locking grooves of the steel ST nipples are case

hardened for resistance to brinelling where high cycle rates and

pressure surges are encountered.

4. The ST is an “Interchange” coupling since it dimensionally and

functionally interchanges with similar couplings made by other

manufacturers

APPLICATIONS INTERCHANGEABILITY

NPTF = DRYSEAL USA (AMERICAN) STANDARD

ST Series is the ideal coupling ST Series couplings are known PIPE THREAD VERSUS A STANDARD NPT THREAD

where maximum flow is required as “industrial interchange”

in such applications as high couplings because they are HOW A LEAK FREE JOINT IS ACHIEVED

pressure water and steam dimensionally and operationally NPT threads, when assembled without a sealant, leave a spiral leak path

washers, carpet cleaners, mold interchangeable with similar at the crest-root junction. To seal pressurized fluid, NPT threads need a

coolant lines, etc. Their smooth couplings manufactured by suitable sealer.

open bore allows almost complete Hansen, Foster and others.

cleanability for applications such NPTF threads (Dryseal), on the other hand, when assembled, do not

as food processing, fluid and dye STEEL NIPPLES leave such spiral leak path. This is because they have controlled truncation

transfer lines, etc. at the crest and root, ensuring metal to metal crest-root contact prior to,

Steel ST nipples are zinc plated or just as the male-female thread flanks make contact. Upon further

OPTIONS and hardened for resistance to tightening, the thread crests are flattened out until the flanks also make

brinelling in applications where metal to metal contact. Thus, theoretically at least, there is no passage

Seals- Standard seal material is high cycle rates and pressure left for the fluid to leak, provided all surfaces are flawless and dimensions

Buna-N, but ethylene propylene, surges are encountered. exact. In the real world, however, this is not the case and a sealant/lubricant

viton, or neoprene seals are is necessary to achieve a leak free joint even with NPTF threads. The

available. sealant/lubricant fills all imperfections in the surfaces affecting the seal

and provides lubrication to ease assembly and minimize galling.

SPECIFICATIONS

MINIMUM FLOW DATA RATED PRESSURE WITH

BODY FLOW STEEL

SIZE PASSAGE PRESSURE TEST FLOW BRASS STAINLESS NIPPLES

DIAM. DROP (PSI) (GPM) NIPPLES NIPPLES

1/8 .172 11.6 4.0 2,500 PSI 4,200 PSI 2,600 PSI

1/4 .250 5.7 6.0 5,200 6,700 5,500

3/8 .375 1.8 10.0 2,700 5,500 3,500

1/2 .469 3.2 20.0 2,200 3,000 2,700

3/4 .719 1.3 35.0 1,700 1,700 1,700

1 .969 0.8 50.0 1,200 1,700 2,000

1 1/4 1.187 0.8 76.5 1,700 – –

1 1/2 1.437 2.5 125.0 1,400 – –

NOTE: These pressure ratings are based on the ability of the product to contain pressure. High cycling applications at or near rated pressure especially

if swiveling is involved, will shorten the product’s service life.

PLASTIC PROCESS EQUIPMENT, INC. www.ppe.com

e-mail: sales@ppe.com

E 8303 CORPORATE PARK DRIVE W 6385 MONTESSOURI STREET

A MACEDONIA, OHIO 44056-2300 E LAS VEGAS, NEVADA 89113-1186 Toll Free: USA, Canada & Mexico

S 216-367-7000 • FAX: 216-367-7022 S 702-433-6385 • FAX: 702-433-6388 800-362-0706

T TOLL FREE: 800-321-0562 T TOLL FREE: 800-258-8877 Order Fax: 800-223-8305

530