Page 19 - Plastic Process Equipment, Inc

P. 19

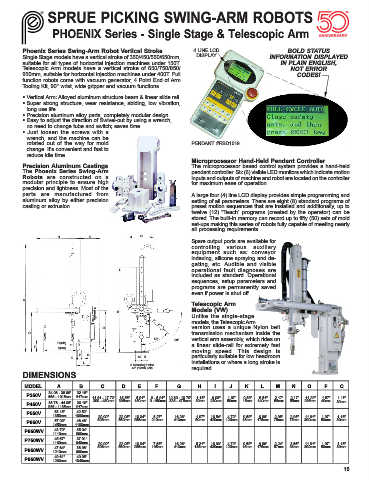

SPRUE PICKING SWING-ARM ROBOTS

PHOENIX Series - Single Stage & Telescopic Arm

Phoenix Series Swing-Arm Robot Vertical Stroke 4 LINE LCD BOLD STATUS

Single Stage models have a vertical stroke of 350/450/550/650mm, DISPLAY INFORMATION DISPLAYED

suitable for all types of horizontal injection machines under 150T. IN PLAIN ENGLISH,

Telescopic Arm models have a vertical stroke of 650/750/850/ NOT ERROR

950mm, suitable for horizontal injection machines under 400T. Full CODES!

function robots come with vacuum generator, 4 Point End of Arm

Tooling Kit, 90° wrist, wide gripper and vacuum functions.

• Vertical Arm: Alloyed aluminum structure beam & linear slide rail.

• Super strong structure, wear resistance, abiding, low vibration,

long use life.

• Precision aluminum alloy parts, completely modular design.

• Easy to adjust the direction of Swivel-out by using a wrench,

no need to change tube and switch; saves time.

• Just loosen the screws with a

wrench, and the machine can be

rotated out of the way for mold PENDANT #RBD1019

change. It’s convenient and fast to

reduce idle time.

Microprocessor Hand-Held Pendant Controller

Precision Aluminum Castings The microprocessor based control system provides a hand-held

The Phoenix Series Swing-Arm pendant controller. Six (6) visible LED monitors which indicate motion

Robots are constructed on a inputs and outputs of machine and robot are located on the controller

modular principle to ensure high for maximum ease of operation.

precision and lightness. Most of the

parts are manufactured from A large four (4) line LCD display provides simple programming and

aluminum alloy by either precision setting of all parameters. There are eight (8) standard programs of

casting or extrusion. preset motion sequences that are installed and additionally, up to

twelve (12) “Teach” programs (created by the operator) can be

stored. The built-in memory can record up to fifty (50) sets of mold

set-ups making this series of robots fully capable of meeting nearly

all processing requirements.

O

D E

Spare output ports are available for

controlling various auxiliary

equipment such as: conveyor

indexing, silicone spraying and de-

gating, etc. Audible and visible

operational fault diagnoses are

included as standard. Operational

sequences, setup parameters and

programs are permanently saved

even if power is shut off.

A

Telescopic Arm

Models (VW)

B

Unlike the single-stage

models, the Telescopic Arm

G version uses a unique Nylon belt

C transmission mechanism inside the

50° vertical arm assembly, which rides on

90°

H (min)

F a linear slide-rail for extremely fast

I (max) J

moving speed. This design is

P Q

K M N particularly suitable for low headroom

L installations or where a long stroke is

6 Mounting Holes

.47” (12mm) dia. required.

DIMENSIONS

MODEL A B C D E F G H I J K L M N O P Q

34.06 - 39.96" 32.16"

P350V 865 - 1015mm 817mm 11.81 - 17.72" 15.55" 5.91" 0 - 5.91" 12.80 - 18.70" 1.18" 9.06" 1.97" 0.59" 5.51" 2.17" 2.17" 11.22" 1.57" 1.18"

38.78 - 44.68" 36.10" 300 - 450mm 395mm 150mm 0 -150mm 325 - 475mm 30mm 230mm 50mm 15mm 140mm 55mm 55mm 285mm 40mm 30mm

P450V 985 - 1135mm 917mm

53.15"

42.52"

P550V 1350mm 1080mm 20.00" 22.05" 10.04" 8.27" 16.26" 1.97" 16.54" 4.72" 0.59" 6.89" 2.95" 2.95" 11.81" 1.97" 1.18"

57.09"

46.46"

P650V 1450mm 1180mm 508mm 560mm 255mm 210mm 413mm 50mm 420mm 120mm 15mm 175mm 75mm 75mm 300mm 50mm 30mm

43.70"

35.04"

P650WV 1110mm 890mm

45.67"

37.01"

P750WV 1160mm 940mm 20.00" 22.05" 10.04" 7.68" 16.26" 5.31" 16.93" 4.72" 0.59" 6.89" 2.24" 3.66" 11.81" 1.97" 1.18"

38.98"

47.64"

P850WV 1210mm 990mm 508mm 560mm 255mm 195mm 413mm 135mm 430mm 120mm 15mm 175mm 57mm 93mm 300mm 50mm 30mm

49.61"

40.95"

P950WV 1260mm 1040mm

19